Hi there! 👋

Fill out the form below to start a conversation with us on WhatsApp.

Hi there! 👋

Fill out the form below to start a conversation with us on WhatsApp.

- Home

- Air Dunnage Bag

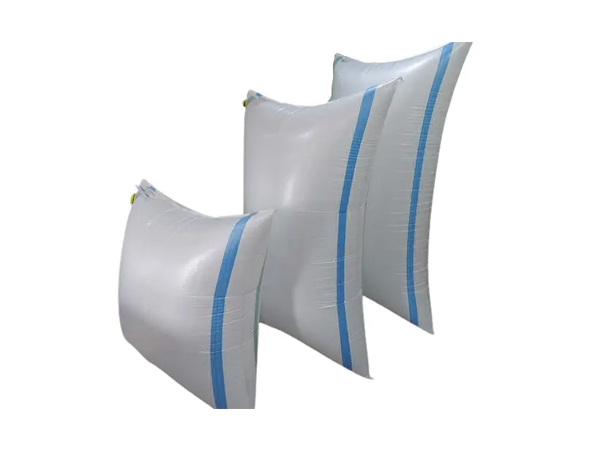

Air Dunnage Bag Manufacturers in Pune – Sai Enterprises

Sai Enterprises is the leading air dunnage bag manufacturers in Pune. Our bag is taking the world of securing freight into a new area. Our bag is easy convenient to deploy in securing and stabilizing cargo when transporting goods by truck, rail, or ocean.

Basically, our bag fills empty spaces in cargo containers to avoid shifting and resulting damage. Made of robust materials, our bag is designed to survive transport challenges, a handy substitute for conventional dunnage material such as wood or foam.

With their flexibility, dunnage bag is best suited for an assortment of cargoes ranging from palletized cargo to heavy machinery. The character of inflation and deflation is such that smooth and effective unloading and loading operations are easily completed.

We are trusted Air Dunnage Bag Manufacturers in Chakan, Moshi, Bhosari, Ranjangaon, Hadapsar, Shirwal, Shikrapur, Talegaon, Ranjangaon

Why Choose us for Air Dunnage Bag in Pune?

Our Air Dunnage Bag is an indispensable component of transit load stabilization and prevents expensive damage. We are inflatable bag which take up space and level loads to the same degree in containers, trucks, or vehicles.

We have several wonderful advantages Improved Load Stabilization. We prevent shifting and impact damage altogether, and product loss is minimized to a bare minimum. Through load restraint, we reduce the risk of injury to personnel and equipment in transit.

Cost-Effectiveness are easier and faster to install compared to other former void fills, and recyclable in most cases. We have diversification of strength and size ranges to accommodate all cargoes and means of transport.

We are reputed Air Dunnage Bag Suppliers in Chakan, Moshi, Bhosari, Ranjangaon, Hadapsar, Shirwal, Shikrapur, Talegaon, Ranjangaon

Types Of Air Dunnage Bag:

Being suppliers and dealers of Air Dunnage Bag in Pune, we are providing different types as per different regional uses as follows.

Paper Dunnage Bag:

We consist of an inner liner of polyethylene to keep air and outer kraft paper for added support. We are flexible with different plies thickness to support varying load weights.Polypropylene Paper Laminated Bag:

We take advantage of the strength of woven polypropylene and paper, with lamination build. The lamination also provides added water and puncture resistance, providing extra security for sensitive cargo.Level 0 Air Bag OTR:

We are produced for use in over the road transport. We are used for short range, and light loads. We are a cost-effective choice for regional haulage.Woven Polypropylene Bag:

Made of stiff woven polypropylene, the bag is extremely tear and water resistant. Our withstanding heavy weights are capable of and extreme conditions, dry and wet.Level 1 Air Bag:

We are utility bag, built for all-purpose truck and container hauling. We are designed to carry heavy to medium loads. We are extremely popular, and suitable for different shipping needs.

Technical Specification of Air Dunnage Bag:

We have added below a technical sheet of air dunnage bag in Pune that provides more technical information such as:

| Specifications | Notes | |

|---|---|---|

| Material - Outer Layer | Poly woven PP, Kraft Paper multiple plies, or Combination, High tensile strength. Coated or Uncoated varieties available | Poly woven for heavy-duty, Kraft for lighter applications. Coatings enhance moisture and tear resistance. Variation in GSM (grams per square meter) indicates strength. |

| Material - Inner Layer | Co-extruded Polyethylene (PE) or Polyamide (PA) films, multiple layers. Thickness measured in microns. | PE for standard applications, PA for enhanced puncture resistance and air retention. Multi-layering improves durability. |

| Valve Type | Turbo flow, Striker, Cross, High-flow venturi valves, One-way self-sealing valves | Turbo Flow and High-flow valves optimize inflation/deflation speed. One-way valves ensure pressure retention. |

| Working Pressure | 0.2 bar to 0.8 bar (2.9 psi to 11.6 psi), variable by bag type | Pressure rating depends on cargo weight and void size. Higher pressure bag for heavier loads. |

| Burst Pressure | Typically, 3x Working Pressure or higher | Specifies the maximum pressure the bag can withstand before rupturing. Safety-critical parameter. |

| Size/Dimensions | Variable: Width 60cm-120cm, Length 90cm-240cm+, Customizable sizes available | Sized to fit specific void spaces in trucks, containers, railcars, etc. Customization enables optimized void fill. |

| Void Fill Capacity | 5cm to 70cm+ | Maximum space that a dunnage bag will adequately fill. |

| Temperature Resistance | -20°C to +60°C (-4°F to +140°F) Standard, Extended range options possible. | Variation will depend on manufacture. Extreme conditions can require specially ordered bags. |

| Air Retention | Minimal pressure loss over extended periods, test methods available e.g., pressure decay tests | Quality bags maintain pressure for the duration of transport. Air retention is highly dependent on the valve quality and the inner layer material. |

| Compression Strength | Varies widely, typically rated in pounds or kilograms | Indicates the load-bearing capacity of the inflated bag. Directly relates to cargo stabilization. |

| Recyclability | Materials are typically recyclable (PE, PP, Paper) | Increasing focus on sustainable packaging solutions. |

| AAR Verification | Association of American Railroads (AAR) verified Levels level 1-5. | AAR verification assures the bag has met certain quality and performance metrics. |

| Inflation tools | Venturi air inflators (standard, digital and auto shut-off), and electrical or battery-powered inflators. | Digital and auto shut-off inflators aid in correct bag inflation. |

| Leak testing | Many manufacturers will use submerged air leak tests to assure quality. | This step assures the consistent quality of produced bags. |

Features and Benefits of Air Dunnage Bag:

Being air dunnage bag distributors in Pune, we possess numerous major benefits when it comes to cargo securing. Some of the benefits are given below.

Enhanced Cargo Stabilization:

We can efficiently utilize void space, and hence cargo cannot move around while being transported. This reduces movement damage to a great extent, vibration damage, and impact damage.Cost-Effectiveness:

Relative to other conventional approaches such as lumber bracing, dunnage bags are cheaper. We eliminate the cost of labour needed in assembling intricate bracing systems and minimize product damage, which is very costly.Improved Efficiency:

Our easy and fast technique to install and deflate, ensuring easy loading and unloading. This saves precious time and improves overall logistics efficiency.Flexibility:

We are adaptable to support different types of cargoes and container capacities, hence being appropriate for different industries and shipping requirements. We can be applied to trucks, railcars, and shipping containers.Environmental Friendliness:

Mostly we are constructed from recyclable materials, which enhance the environmentally friendly mode of shipping. Also, proper application will forestall the use of excess packaging material.

Applications Of Air Dunnage Bag:

Serve as air dunnage bag stockists in Pune, we are having quite useful bag within the logistics and shipping industry. Some of the applications are given below.

Securing cargo internally within Shipping Containers:

We actually seal void spaces between loads of cargo so it does not move and become damaged during rail, sea, and truck transportation.Bracing Loads in Truck Transport:

Our dunnage bags find use within truck trailer bracing such that commodities remain level along the journey on various road terrain.Preventing Railcar Movement:

We provide necessary support to prevent load movement in railcars when moving heavy or bulkily shaped items that tend to shift.Aiding Fragile Commodities:

By cushioning and supporting the load, dunnage bags reduce the likelihood of inflicting damage on sensitive goods during transit.Taking Up Space and Creating Space:

Our properly fill up the volumes in cargo loads, filling space to the fullest, and avoiding cargo collapse or settlement.

Being best air dunnage bag manufacturers in Pune at Sai Enterprises, we provide a variety of types for various transport applications. Our bag is effective in stabilization of the cargo, cost reduction, and enhanced logistics through elimination of movement and damage during transit. We are constructed from recyclable heavy-duty materials that can be applied in various applications such as shipping containers, trucks, and railcars. Our bag is quality-oriented and provides technical specifications to ensure and meet diverse industries standard. For more details and best deals contact with us.